DELMIA

Optimize Your Production. Accelerate Innovation.

Bridge the virtual and real worlds to improve productivity, collaboration, and operational excellence.

What is DELMIA?

DELMIA is an advanced digital manufacturing platform that empowers teams to simulate, optimize, and experiment with processes in a virtual environment. This model-based approach supports faster, data-driven decision-making, reduces risk and cost, and enhances operational flexibility.

By leveraging AI-powered generative experiences and virtual twins, DELMIA ensures your factory or production line is always aligned with the future—smarter, safer, and more efficient.z

DELMIA Digital Manufacturing Portfolio

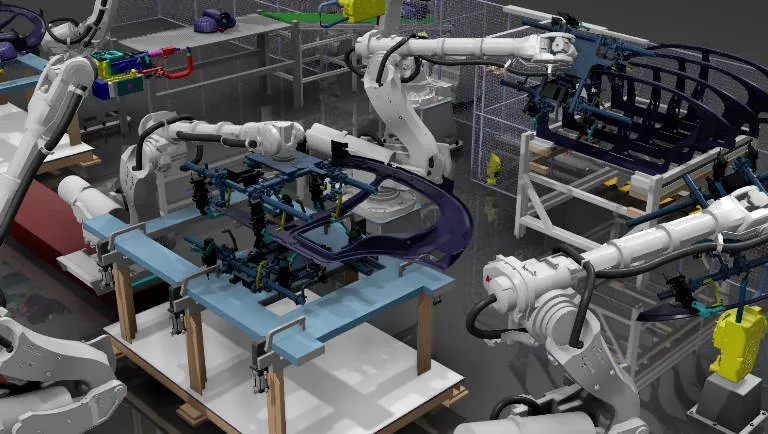

DELMIA Industrial Engineering

Simulate and optimize production lines with 3D modeling and virtual twins.

Key capabilities:

- Robotics programming and simulation

- CNC machining and CAM automation

- Additive manufacturing workflows

- Ergonomics analysis and process planning

This solution supports agile, safe, and collaborative manufacturing environments through real-time data integration.

DELMIA Apriso

A complete Manufacturing Operations Management (MOM) solution offering:

- Real-time production monitoring

- Quality control

- Labor and time tracking

- Inventory and warehouse management

Apriso bridges virtual simulations with real operations, supporting process standardization, regulatory compliance, and global production efficiency.

DELMIA Augmented Experience

Use augmented reality to overlay 3D work instructions directly onto physical components for:

- Precise assembly and inspection

- Real-time, step-by-step guidance

- Enhanced productivity and first-time-right results

This AR solution enhances accuracy, boosts quality, and integrates seamlessly with virtual twins

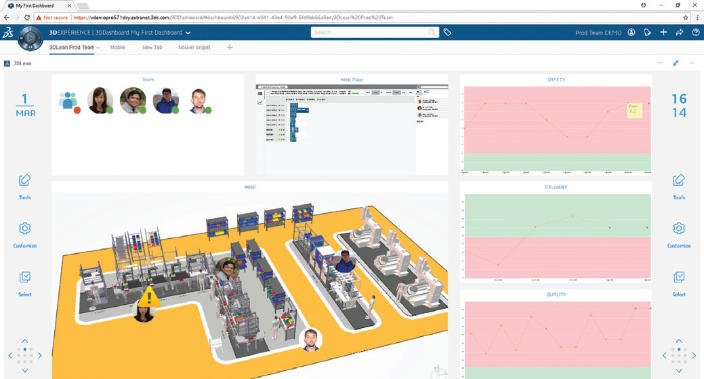

DELMIA 3DLean

A collaborative web application built on lean manufacturing principles.

3DLean helps teams:

Drive continuous improvement using structured workflows

Visualize and solve problems using 3D content and KPIs

Align on goals across departments and locations

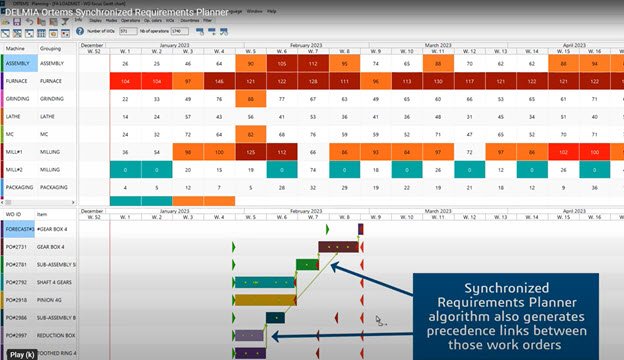

DELMIA Ortems & DELMIA Quintiq

Advanced Planning and Optimization (APO) tools for complex operations:

- DELMIA Ortems: Agile planning and scheduling for production

- DELMIA Quintiq: End-to-end value chain planning, including:

- Sales & Operations Planning (S&OP)

- Workforce and logistics optimization

These tools help balance resource constraints with business objectives, enabling feasible, optimized plans across every planning horizon.

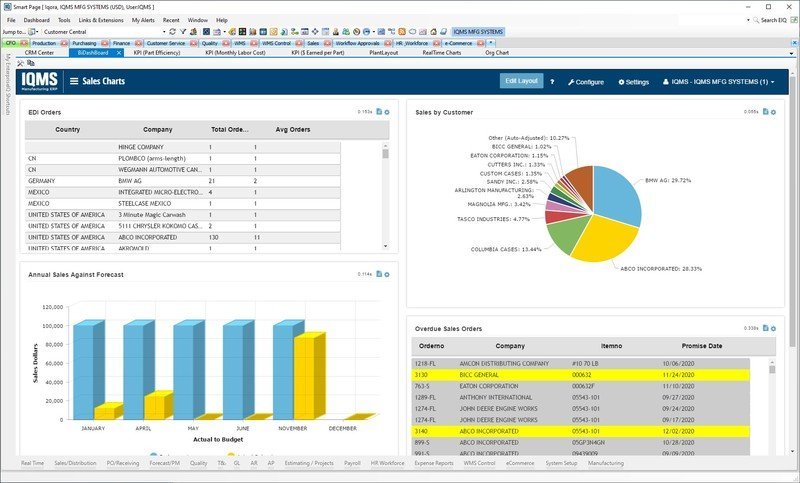

DELMIAWorks

An integrated manufacturing ERP system tailored to mid-market manufacturers.

Covers all key operational areas:

- Quoting, procurement, and production scheduling

- Inventory, warehouse, and supply chain management

- Quality management and real-time production monitoring

- Financials and business analytics

With its “shop floor first” approach, DELMIAWorks gives you full visibility and control over your operations.

Key Features of DELMIA

Virtual Process Simulation

Model and simulate entire factory operations, including layout, robotic work cells, and assembly processes in 3D to optimize workflows digitally.

Production Planning & Scheduling

Balance workloads, allocate resources, and adapt to shifting demands in real-time to maximize efficiency.

Manufacturing Operations Management

Monitor performance, quality, and production status to make rapid, informed decisions and resolve issues quickly.

Collaboration & Integration

Create a digital thread across engineering, production, and business systems with seamless CAD, PLM, and ERP integration.

Continuous Improvement

Leverage analytics and feedback loops to identify inefficiencies, reduce waste, and promote lean manufacturing across your sites.

Ready to Digitally Transform Your Operations?

At Ultimate Solutions, we bring the full power of DELMIA to your factory floor. Whether you need to streamline operations, boost quality, or accelerate production planning, our team is ready to guide you every step of the way.

Contact us today to schedule a demo or consultation.

Discover how DELMIA can future-proof your manufacturing operations.